Sustainable solutions

Soilless farming and microalgae production are fast-growing industries, looking for solutions to increase their sustainability and reduce costs.

Greenhouses...

…increasingly contain hydroponic systems to grow crops. The majority of Europe's greenhouse tomatoes are currently produced in these soilless systems. They provide plants directly with water and nutrients, increasing crop productivity and using water more efficiently than conventional production methods.

The challenge

Fertilizers added to the drain water for fast and healthy plant growth, have to be removed so they don‘t pollute the environment. Yet, high-tech water treatment systems are expensive.

The REALM solution

We develop a cost-effective water treatment system to help farmers recycle their drain water at no or reduced cost. The drain water from soilless culture systems can be used to grow microalgae. They remove the fertilizers and can then be sold to produce bio-products, generating extra revenue.

Microalgae...

... are tiny oxygen producers. Rich in proteins, omega fatty acids and health-beneficial compounds, microalgae represent a sustainable source for food, feed, agrochemicals and cosmetics. Even though they have a simple life-style their cultivation requires water, nutrients, CO2 and energy.

The challenge

At the moment, we cannot fully unlock the potential of microalgae. The price of water, nutrients like nitrogen, CO2, energy, and highly trained personal make the cultivation of microalgae costly.

The REALM solution

We rethink the way we grow microalgae to reduce their production costs: using drain water from greenhouses as a source of free water and nutrients, capturing CO2 from the air, using solar energy, as well as new technology to automate production and control it remotely.

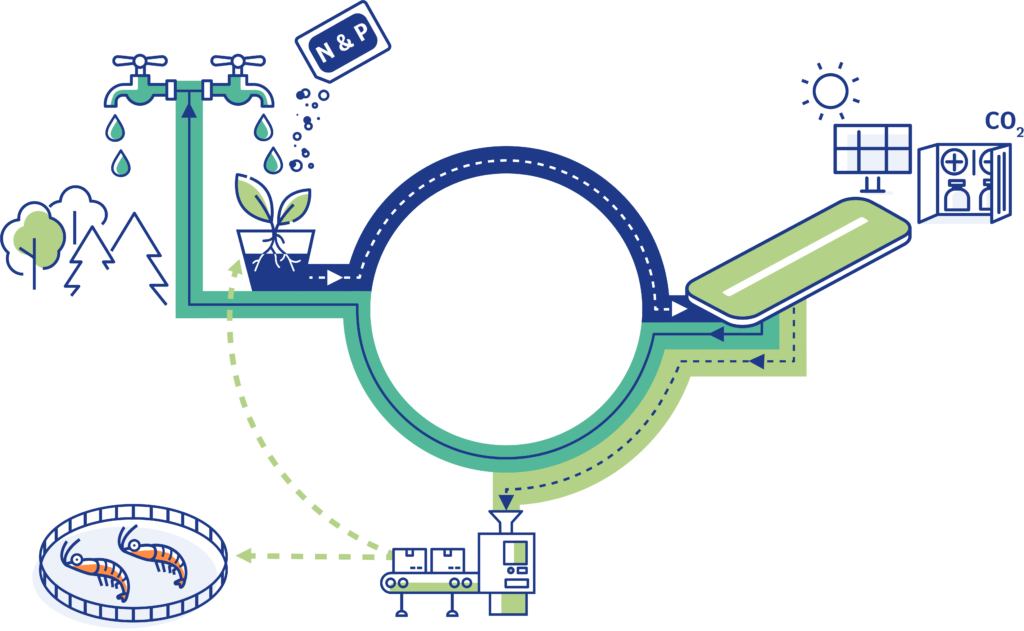

Circular production of microalgae

- In REALM, we use circular agriculture to produce microalgae which will then clean the drain water for safe reuse or release.

- The second major innovation is applying the continuous cultivation mode on an industrial scale.

- Additionally, we are developing new systems to cultivate and harvest microalgae automatically, ensuring maximum growth rate of the microalgae and reduced labour costs. Newly developed sensors will monitor the composition of the growth medium, the quality of the culture and other biological, physical and chemical variables of microalgae production. This will greatly improve process control and consequently productivity. By coupling the collected data with artificial intelligence, we will develop predictive models and digital twins to determine the most productive cultivation setup and conditions for each microalgae strain and environment; for instance, the optimal cellular concentration of microalgae in the growth medium, important for optimal exposure of microalgae to light.

The process

- Farmers add nitrogen and phosphate to the irrigation water. The water that is not used by the plants runs off and is collected in drain water basins.

- This drain water is then transferred to microalgae cultivation systems such as raceway ponds or photobioreactors.

- Once the concentration of fertilisers reaches below legal levels, the water is released to the environment or transferred back to the greenhouse.

- Microalgae are harvested automatically and continuously. They are transported to a processing facility and transformed into bio-products for agri- and aquaculture.

- The CO2 needed by the microalgae is partly captured directly from the air. Solar energy runs the carbon capture technology, and the cultivation and harvesting system.

Microalgae products

Growing microalgae only requires water, energy, CO2 and nutrients. If these inputs come from sustainable resources, the production of microalgae becomes more environmentally friendly. Microalgae products are then more sustainable than their counterpart products. In REALM, we develop such microalgae-based products for:

Agriculture

Microalgae produce compounds that act against common plant pathogens, or promote root development and help the plant grow healthier. These compounds can be transformed into biopesticides and biostimulants. Both are essential for farmers. These biological alternatives to agrochemicals help farmers meet the growing demand for food in a more sustainable way. Using these products both increases crop productivity and reduces chemical pesticide and fertiliser use– a goal set out by the EU's Green Deal.

Aquaculture

Microalgae are rich in nutrients and are at the base of the food chain. They can be fed to zooplankton which then serve as feed for fish in aquaculture. Microalgae can also directly be fed to baby fish, shrimp and clams. Due to their high content of omega-3 polyunsaturated fatty acids, microalgae represent a sustainable replacement for fish oil. It is currently produced from fish and places a great strain on our oceans.

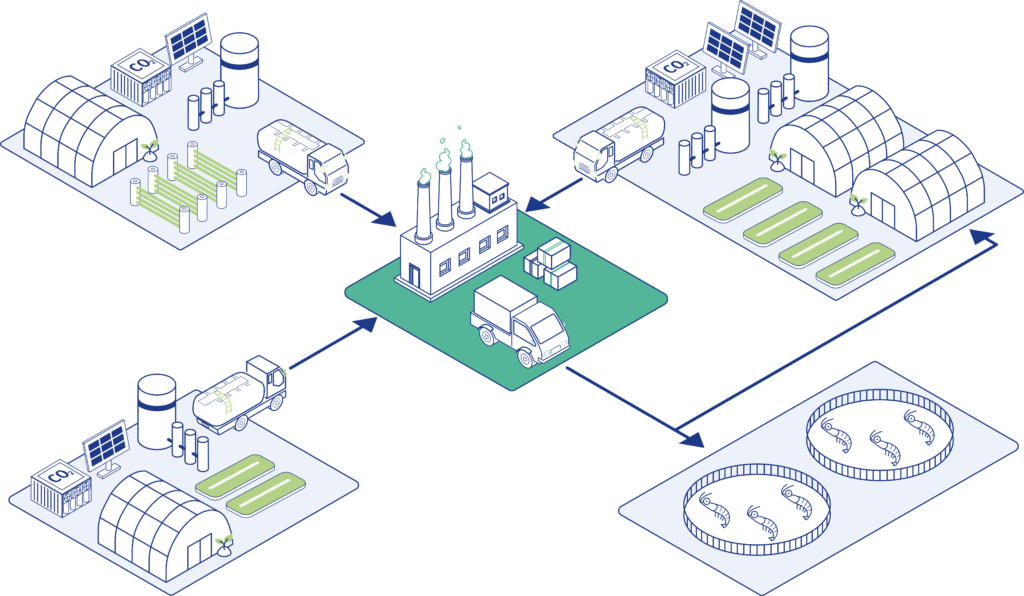

Decentralised production of microalgae

Today most microalgae producers run small or medium sized businesses. Increasing the capacity of production spreads the costs over more goods, reducing the cost per good and making the business more viable. Most microalgae producers are lacking this economy of scale.

Decentralising the production of microalgae is an innovative way for the industry to reach the scale necessary to unlock the full potential of microalgae.

The process

- In a decentralised operation, cultivation and processing of microalgae happens at different facilities, using raceway ponds or photobioreactors.

- Just like in the dairy industry, microalgae producers grow this valuable resource and deliver it to a central production facility.

- There, biofertilisers, biostimulants and aquaculture feed are produced.

- Greenhouse farmers and aqua culturists can purchase the produced goods as sustainable alternatives to commercially available products.

Raceway pond or tubular photobioreactor?

Microalgae can be produced in many different cultivation systems. These are commonly divided into open systems such as raceway ponds and closed systems like tubular photobioreactors.

In these closed-loop, open recirculation channels a paddle wheel propels the microalgal culture. Raceway ponds have the advantage of low-cost investment and operation but are more prone to contamination by other microorganisms and lower biomass productivity.

In connected, transparent tubes a pump circulates the culture. Tubular photobioreactors offer a more controlled environment and, consequently, higher productivity. But they produce biomass at a higher cost.

Depending on the surrounding conditions and the desired final product, one cultivation system is more suitable than the other.

In Northern Europe and other low-light environments, a tubular photobioreactor is preferable to a raceway pond as it exposes microalgae better to light. A raceway pond is the preferable system when cultivating biomass for low-cost applications.

Adaption of the REALM concept

Embark on our endeavour, become part of the REALM community and help make the REALM concept a reality.

![UKRI logo [W] UKRI logo [W]](https://realmalgae.eu/wp-content/uploads/elementor/thumbs/UKRI-logo-W-qpvs3ojy8iduv0fhwct4qqi0nrhb6qt3tstfu87keo.png)